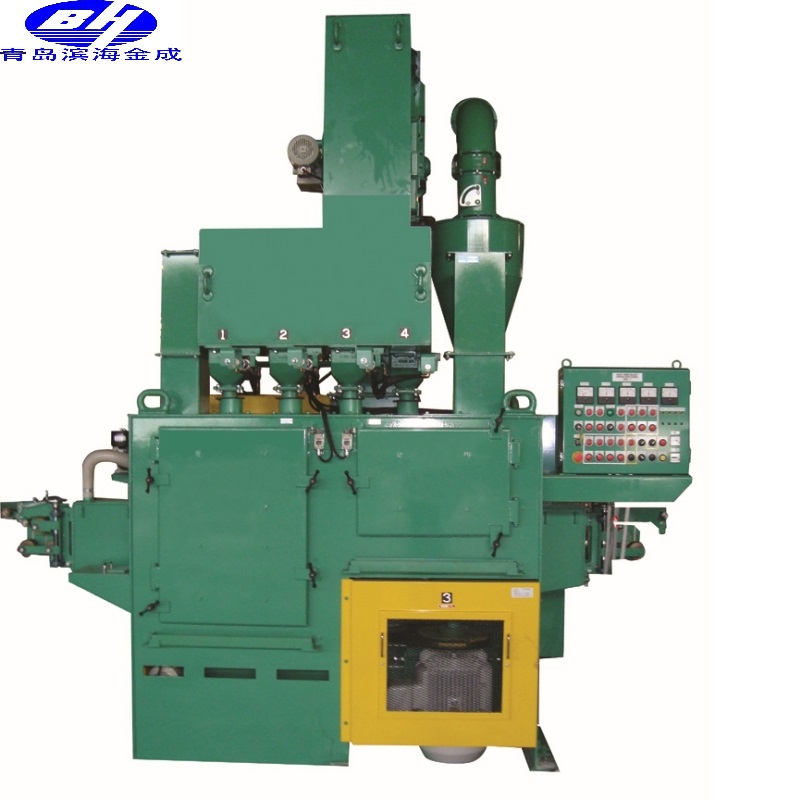

Q341 Series Reinforced Txhaj Tshuaj Blasting Tshuab

1. Txheej txheem cej luam:

Q341 series Reinforced txhaj blasting tshuab tseem hu ua nuv-turntable multi-chaw nres tsheb tua blasting tshuab.Nws yog hom tshiab tua blasting tshuab uas yog tus kheej tsim los ntawm peb lub tuam txhab.

Cov khoom lag luam no yog cov khoom siv kho dua tshiab ntawm Q37 Series Hook hom Txhaj Tshuaj Blasting Tshuab hauv peb lub tuam txhab General series ntawm cov khoom.

Txais 2stations tsim, uas tuaj yeem paub txog cov txheej txheem ntawm kev thauj khoom thiab tshem tawm cov khoom ua haujlwm hauv lwm qhov chaw nres tsheb thaum ib qho chaw nres tsheb raug tua.

Feem ntau yog siv los ntxuav qhov chaw los yog ntxiv dag zog rau kev kho me me forgings, castings thiab cov khoom siv.Tshwj xeeb tshaj yog tsim rau cov khoom ua haujlwm uas yooj yim rau dai thiab tua ntawm sab thiab sab saum toj, xws li lub cev muaj zog, txuas rods, iav shafts, cylindrical iav, clutch diaphragms, bevel iav thiab lwm yam khoom.

Los ntawm kev txhaj tshuaj blasting, tsis tsuas yog tuaj yeem tshem tawm cov xuab zeb, xeb, oxide, vuam slag, thiab lwm yam ntawm qhov chaw ua haujlwm, nws tuaj yeem txhim kho qhov nyuaj ntawm qhov chaw, tuaj yeem txhim kho qhov kev ntxhov siab sab hauv ntawm cov khoom ua haujlwm. , ua tiav lub hom phiaj ntawm kev ntxiv dag zog, txhim kho qhov ua haujlwm-dawb qaug zog ua haujlwm.Ntxiv mus, Nws tuaj yeem ua rau cov khoom ua haujlwm tau txais cov xim hlau zoo sib xws, thiab txhim kho cov txheej txheem zoo thiab tiv thaiv corrosion ntawm cov khoom ua haujlwm.

Customized raws li qhov sib txawv workpieces, non-standard tsim thiab manufacturing.

2. Lub hauv paus ntsiab lus ua haujlwm:

Cov khoom lag luam no feem ntau muaj 2 chaw nres tsheb, ib qho yog qhov chaw thau khoom thiab tshem tawm;lwm qhov yog qhov chaw nres tsheb tua blasting, ob qhov chaw nres tsheb sib hloov tau.

Tom qab thauj cov khoom ua haujlwm hauv qhov chaw thau khoom thiab tshem tawm, nws yuav nres tom qab ncav cuag qhov chaw nres tsheb tua blasting uas tau tsav los ntawm lub tshuab tig.Lub sijhawm no, lwm qhov chaw nres tsheb tuaj yeem txuas ntxiv thauj lossis tshem tawm.

Lub workpieces ntawm qhov chaw txhaj tshuaj blasting pib tig nyob rau hauv qhov kev txiav txim ntawm tus nuv.Lub tshuab txhaj tshuaj blasting pib ua haujlwm.

Tom qab kev ntxuav tiav lawm, qhov chaw thau khoom thiab tshem tawm thiab qhov chaw txhaj tshuaj blasting yog sib pauv.Rov ua dua kom txog thaum tag nrho cov workpieces raug ntxuav.

3.Machine Compositions:

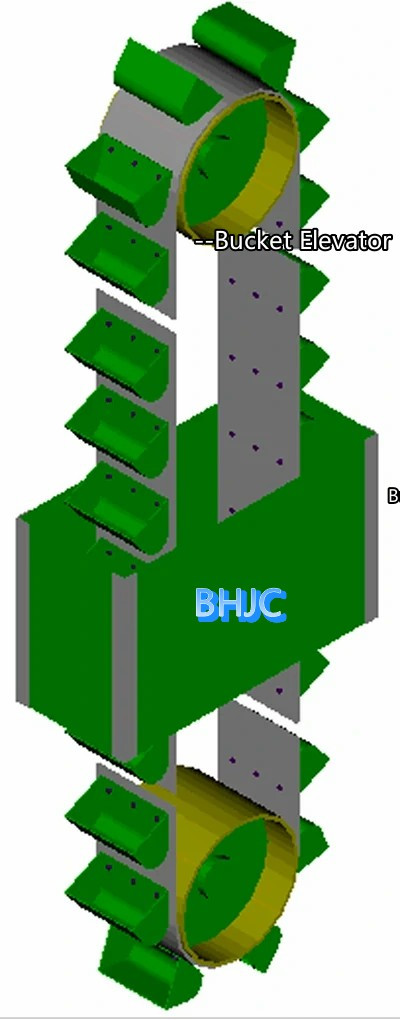

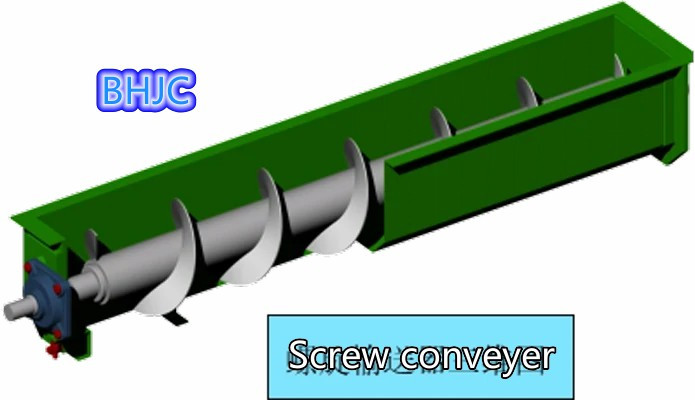

Q341 Series Reinforced Shot Blasting Machine (Lub tshuab sib txuas-turntable txhaj tshuaj blasting tshuab) yog tsim los ntawm: Txhaj tshuaj tua blasting tu chav;Lub rooj zaum;Thoob of elevator;Separator;Ntsia Hlau Conveyor;Txhaum Blaster Assembly;Hook thiab Platform;Hook rotation txo Device;Turntable Revolution Device;thiab Steel Shot Supply System;Plua plav Tshem Tawm System;Hluav taws xob tswj System;lwm.

4.Main technical parameters:

| TSIS MUAJ. | Yam khoom | Parameter | Chav tsev |

| 1 | Max.loading rau ib tug nuv | 280 | kg |

| 2 | Max.dimension ntawm workpiece | φ56 (EX Diameter) / 300 | mm |

| φ28 (IN Diameter) / 300 | mm | ||

| 3 | Tag nrho cov tawg ntim ntawm lub taub hau impeller | 2 * 180 | kg/min |

| Tag nrho lub zog ntawm lub taub hau impeller | 2 * 11 | kW | |

| Blasting ceev ntawm lub taub hau impeller | 70-80 ib | m/s | |

| 4 | Lifting peev ntawm lub thoob of elevator | 30 | T/H |

| Lub zog ntawm lub thoob of elevator | 3.00 Nws | KW | |

| 5 | Fractional koob tshuaj ntawm lub separator | 30 | T/H |

| 6 | Tus nqi xa khoom ntawm Screw conveyor | 30 | T/H |

| 7 | Kev sib hloov rotary ceev | 2.7 | r / min |

| Kev sib hloov zog | 0.37 ib | kW | |

| 8 | Revolution rotary ceev | 2.5 | r / min |

| Revolution hwj chim | 0.75 ib | kW | |

| 9 | Blasting muaj peev xwm ntawm cov plua plav tshem tawm | 7000 | m3/h |

| Lub zog ntawm cov plua plav tshem tawm | 4 | kW | |

| 10 | Thawj tus nqi hnyav ntawm Steel txhaj tshuaj | 0.5 | T |

| Txoj kab uas hla ntawm cov hlau txhaj tshuaj | f 0.5-0.8 ib | mm | |

| 11 | Tag nrho lub zog | ~ 30 | kw |

5.Qhov zoo ntawm cov khoom:

A.Global Design:

Simulated txhaj koob tshuaj tivthaiv daim duab (nrog rau kev txiav txim ntawm tus qauv, tus naj npawb thiab spatial kev npaj ntawm lub taub hau impeller) thiab tag nrho cov kos duab ntawm lub txhaj koob tshuaj tivthaiv blasting tshuab yog kiag li kos los ntawm lub computer-aided tsim (CAD).

Tom qab ntau lub sij hawm ntawm kev xyaum ua kom zoo, kom ua tiav cov nyhuv txhaj tshuaj zoo meej dua.

Nws yuav xyuas kom meej tias nyob rau hauv lub hauv paus ntawm npog tag nrho cov workpieces yuav tsum tau ntxuav, lub khoob pov tseg ntawm cov hlau txhaj tshuaj yog txo, li no maximizing tus nqi ntawm cov hlau txhaj tshuaj thiab txo qhov hnav ntawm lub phaj tiv thaiv nyob rau hauv lub chav tsev tu.

B. Chav Ua Haujlwm:

Lub cev ntawm kev txhaj tshuaj blasting tu chav txais yuav welded qauv, thiab yog ua los ntawm steel phaj thiab structural steel.

Lub cev ntawm chav ntxuav yog ua los ntawm cov khoom zoo Q235A steel phaj (thickness 8-10mm).Sab hauv phab ntsa yog kab nrog 10 hli tuab "Rolled Mn13" tiv thaiv phaj, thiab txais yuav "Block type" tiv thaiv phaj.

Rolled Mn13 phaj yog qhov kev xaiv zoo tshaj plaws rau cov ntaub ntawv hnav-tiv taus nrog cov yam ntxwv ntawm kev cuam tshuam muaj zog, cov khoom siv siab hnav, thiab lwm yam, nrog "lub neej" lub koob npe nrov, thiab tsis muaj lwm yam hnav-tiv taus cov ntaub ntawv tuaj yeem phim nws txoj haujlwm hardening. .

Cov txiv ntoo loj hexagon uas yog siv los kho cov phaj tiv thaiv yog ua los ntawm cov hlau cam tshwj xeeb, thiab nws cov qauv muaj qhov loj dua qhov sib cuag nrog cov phaj tiv thaiv.

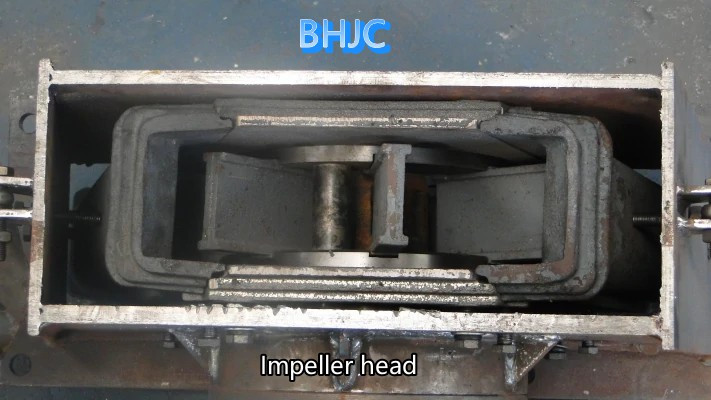

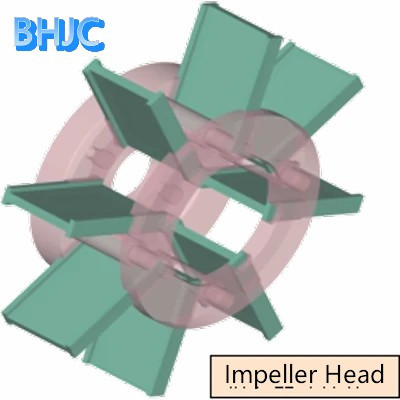

C.Impeller Lub taub hau:

Siv lub peev xwm loj tua blasting (Q037; Shinto. Nyiv txhaj tshuaj blasting tshuab, thev naus laus zis tshiab ntawm kev ua lag luam);nrog kev kub ceev blasting centrifugal txhaj tshuaj blasting ntaus ntawv tuaj yeem txhim kho kev tu kom zoo thiab tau txais kev tu zoo.

Cov phaj tiv thaiv sab saum toj thiab sab tiv thaiv phaj ntawm lub tshuab txhaj tshuaj blasting tag nrho txais cov qauv tshwj xeeb, thiab cov thickness hauv zos ncav cuag 70 hli, uas zoo heev txhim kho cov hnav tsis kam thiab kev pab cuam lub neej ntawm cov phaj tiv thaiv.

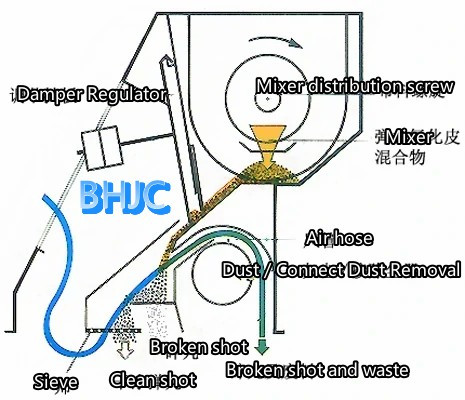

D.Separator:

Txais cov qib siab "BE" hom puv-kab kab hlau rhuav cais.Lub separator yog tsim los ntawm sorting cheeb tsam, conveying ntsia hlau, steel txhaj rau hauv, steel tua tswj rooj vag, thiab lwm yam.

Qhov kev sib cais no tau tsim los ntawm peb lub tuam txhab raws li lub hauv paus ntawm kev nqus cov thev naus laus zis ntawm Swiss GEORGE FISCHER DISA (GIFA) thiab American Pangborn tuam txhab.Nws yog qhov tseeb hom cais ntawm peb lub tuam txhab.

Kev sib cais ua tau zoo tuaj yeem ncav cuag 99.9%.

Lub separator yog ib qho tseem ceeb ntawm cov khoom siv no.Qhov tsim loj ntawm thaj chaw sib cais ncaj qha cuam tshuam rau kev sib cais ntawm qhov sib cais.Yog tias qhov kev sib cais tsis zoo, nws yuav ua rau kom hnav cov hniav tawg, txo nws txoj kev pab cuam lub neej, thiab nce nqi kho.

E.Steel txhaj tshuaj ncig system:

Cov hlau txhaj tshuaj ncig system ntawm tag nrho cov cuab yeej siv los ntsuas tsis siv neeg.Thaum ib feem tsis ua haujlwm zoo lossis daig, nws tuaj yeem ua lub tswb nrov thiab ceeb toom rau qhov tsis raug, kom cov neeg ua haujlwm saib xyuas tuaj yeem ua tiav kev saib xyuas.

F. Lub hom phiaj optimization

Ntawm ob qhov kawg ntawm lub thoob of the elevator, lub tshuab cais, thiab cov ntsia hlau conveyor siv lub tshuab nqus tsev sib khi thiab tus qauv U-zoo li tus thawj coj.

Cov ntsia hlau sib cais thiab cov ntsia hlau conveyor tso tawm cov chaw nres nkoj yog teem rau ntawm qhov deb ntawm qhov kawg.Thiab qhov rov qab conveying hniav yog ntxiv rau qhov kawg ntawm cov ntsia hlau.

Txais cov qauv saum toj no, tuaj yeem txhim kho kev tiv thaiv ntawm cov kabmob thiab ua kom nws lub neej ua haujlwm ntev.

G.Dust tshem tawm qhov system

Siv lub tshuab nqus plua plav nqus plua plav collector ua haujlwm siab, cov plua plav emission yog nyob rau hauv 30mg / m3, thiab rhiav plua plav emission nyob rau hauv 5mg / m3, uas zoo heev txhim kho cov neeg ua hauj lwm kev khiav hauj lwm ib puag ncig.

H.Humanized tsim

Lub chaw thau khoom thiab tshem tawm qhov chaw nres tsheb yog nruab nrog lub grating nrog kev tiv thaiv kev nyab xeeb.Nyob rau hauv cov xwm txheej txawv txav, ib feem ntawm tus neeg teb xov tooj lub cev nkag mus rau hauv qhov chaw grating, thiab lub turntable nres rotating tam sim ntawd kom tsis txhob raug mob rau tus neeg teb xov tooj.

Lub workpiece mus rau lub chaw thau khoom los ntawm tus nuv, ces tig mus rau qhov chaw nres tsheb tua blasting kom nres, thiab ntxuav thaum tig.Cov degree ntawm automation yog siab, cov nyhuv sealing zoo, thiab kev siv zog ntawm cov neeg ua haujlwm tau txo qis heev.

I.Reducer (kev tu-dawb)

Tag nrho cov reducers siv cov roj lubrication tsis tu ncua, uas zam cov roj to ntawm cov roj-lubricated reducers thiab txo cov nqi tu lubrication.

J.Comprehensive qauv

Cov qauv ntawm cov cuab yeej yog compact, layout yog tsim nyog, thiab cov txij nkawm yog yooj yim heev.

1.Ntau cov ntaub ntawv, thov hu rau peb!

6.RAQ:

Muaj ntau ntau hom kev txhaj tshuaj blasting tshuab, txhawm rau muab cov kev daws teeb meem zoo tshaj plaws rau koj cov khoom, thov qhia rau peb paub cov lus teb ntawm cov lus nug hauv qab no:

1.Dab tsi yog cov khoom uas koj xav kho?Tau zoo qhia peb koj cov khoom.

2.Yog tias muaj ntau hom khoom yuav tsum tau kho, qhov loj tshaj ntawm cov khoom ua haujlwm yog dab tsi?Ntev * dav * qhov siab?

3.Dab tsi yog qhov hnyav ntawm qhov loj tshaj workpiece?

4.Dab tsi yog qhov ntau lawm efficiency koj xav tau?

5.Yuav ua li cas lwm yam tshwj xeeb ntawm cov tshuab?